Our Oil and Gas Production Tubing

Endurance Technologies Inc. (ETI) has been involved in the energy industry since 1993. We are well known for the high quality and long-lasting products to help mitigate wear, tubing erosion, and corrosion.

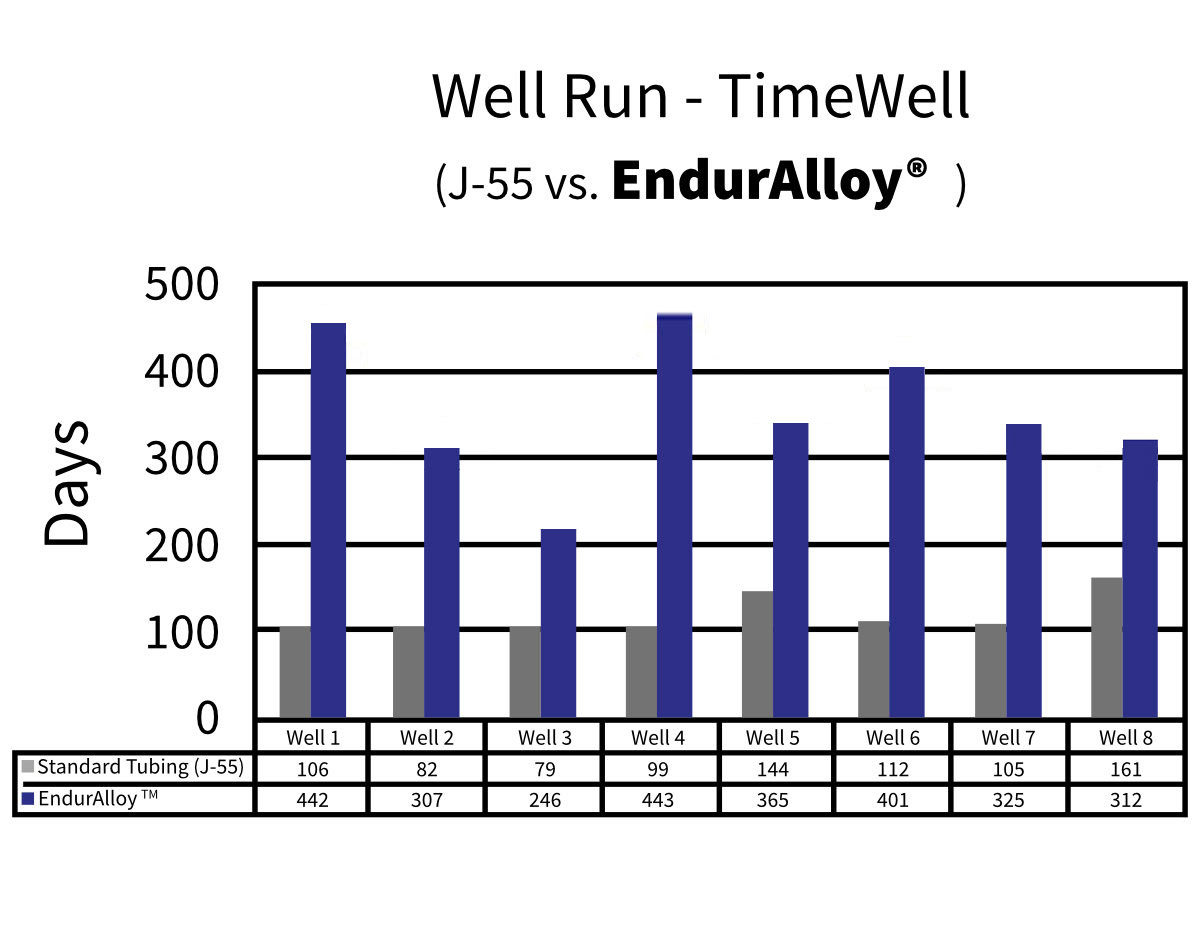

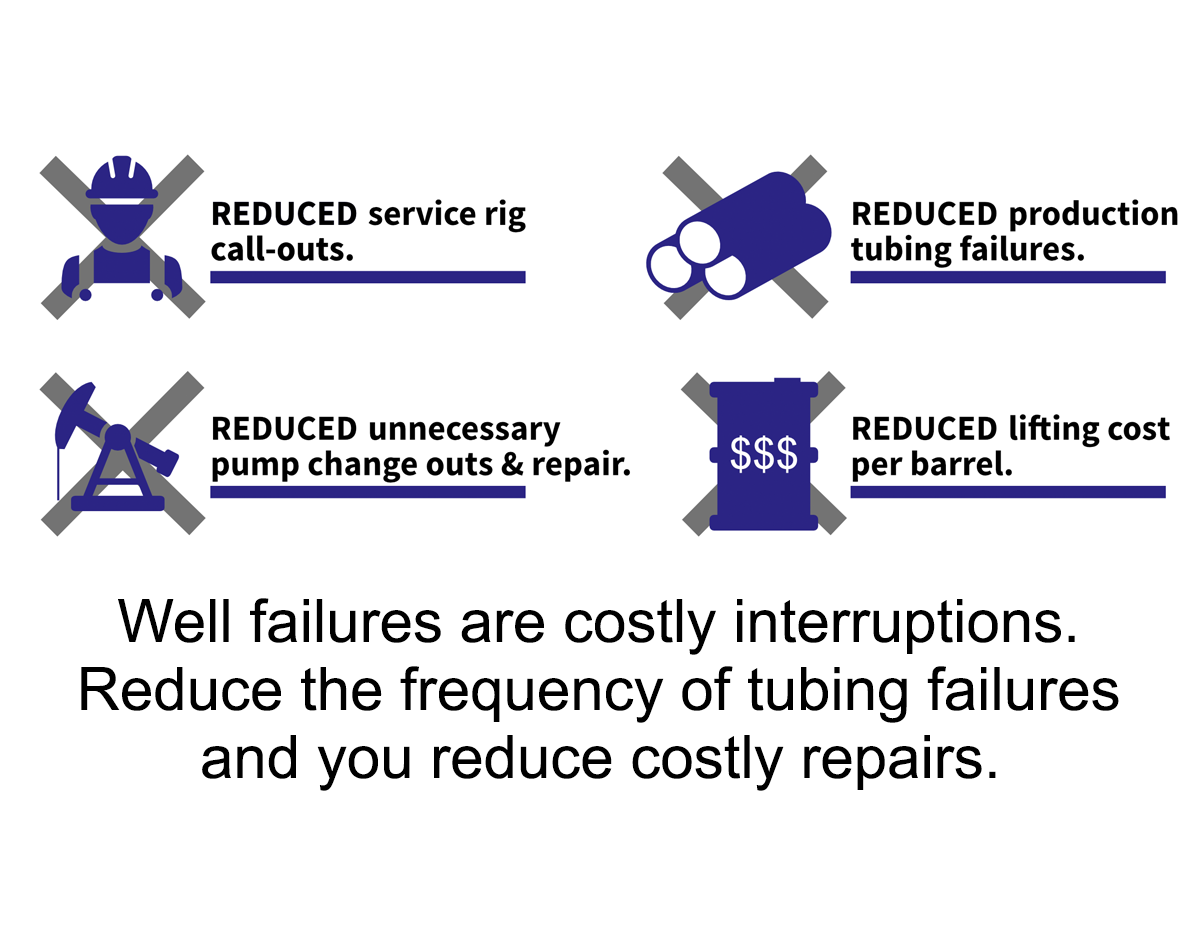

In the oil and gas industry operators are always looking to improve their Mean Time Between Failures (MTBF). This is where ETI's EndurAlloy® (boronized) production tubing and casing becomes the go to product.

Oil and Gas tubing operations depend on maintaining efficiencies, reducing costs. By introducing our EndurAlloy® (boronized) products into your operations, we can help mitigate failures and downtime with your PCP pumps, rod pumps, and jet pumps.

If you find yourself asking these questions:

- How do I prevent hole in tubing failures from rod wear?

- How do I prevent hole in tubing failures from erosion?

- How do I prevent hole in tubing failures from corrosion?

- How do I mitigate downhole wear, erosion, or corrosion in my oil well?

Then our EndurAlloy® (boronized) products could be exactly what you are looking for! EndurAlloy® will help to mitigate your OCTG challenges and help you maintain production for longer and reduce your workover costs per well.

Potential applications:

- Production Tubing

- Pup Joints

- Pipe & Fittings

- Rod Couplings

- Frac Nipples

- Blast Joints

- Production Casing

- Crossovers

- PCP Handing Subs

- Centrifugal Pumps

- Torque Stoppers

- Down-hole tools

If you wish to discuss how our EndurAlloy® (boronized) process can help extend the run life of your OCTG, as well as other steel applications then please reach out to us today.

Endurance Technologies: ENDURALLOY® Product Video

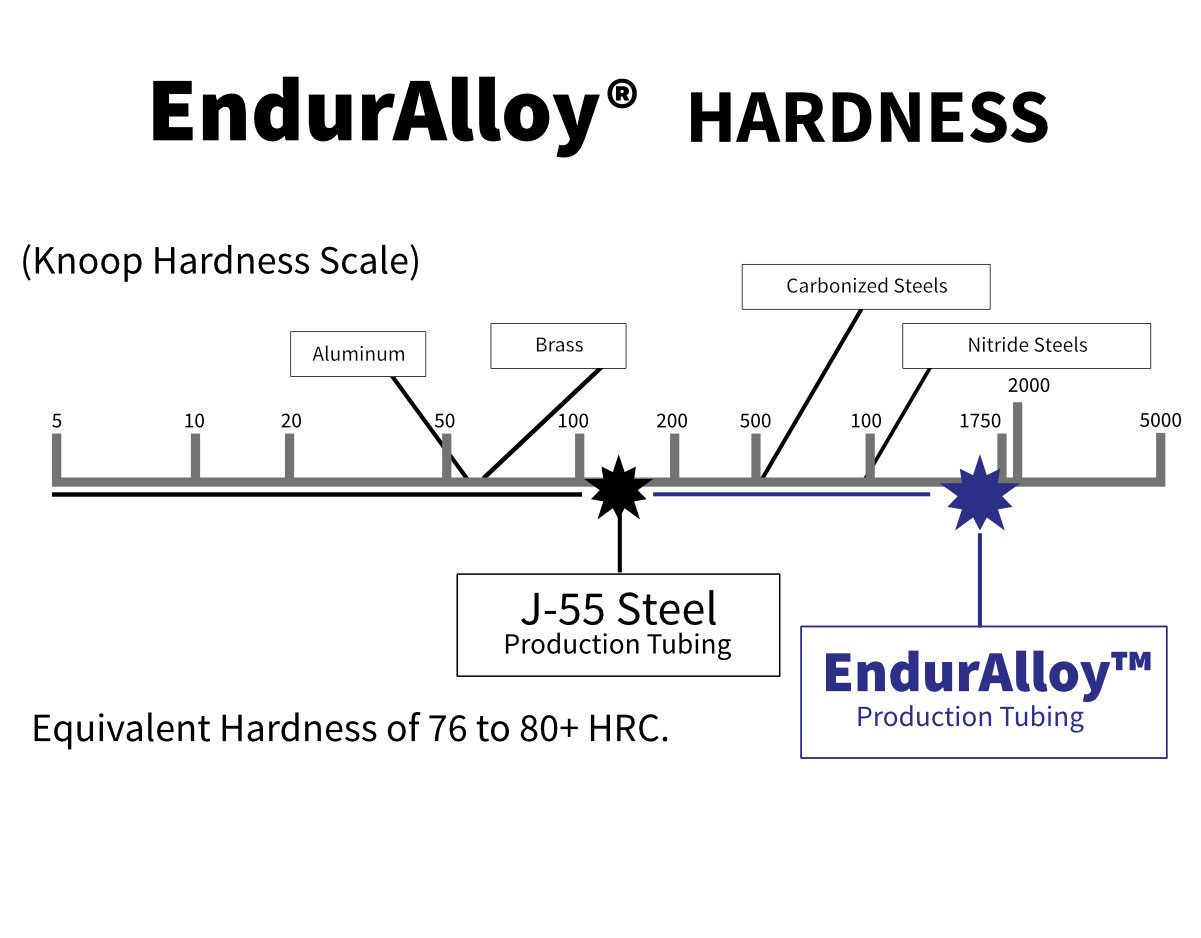

ENDURALLOY®

EROSION, ABRASION & ROD WEAR PROTECTION

Endurance Technologies Inc. supplies field-proven, diffusion alloying technology - ENDURALLOY® (boronized) - for the Oil and Gas industry and applications requiring superior protection against erosion, abrasion, and rod wear environments.

Learn moreENDURALLOY®

CORROSION PROTECTION

Endurance Technologies Inc. supplies field-proven, diffusion Alloying technology - ENDURALLOY® (boronized) - for the Oil and Gas industry and applications requiring superior protection against highly corrosive C02, H2S, acid gas, and water injection environments.

Learn morepipeyard locations

With pipe yards located across Alberta and Saskatchewan and products available world-wide, Endurance Technologies Inc. is your go-to production tubing and casing supplier.

Learn more